Railway Platforms (East – West)

Box Station Railway Platforms (East – West)

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

The client discussed with JMB the possibility of finding GFRP rebar in concrete at the platform edge over a distance of 250 meters on both east and west platforms. JMB researched the possibilities of using ground penetrating radar to capture this information accurately. After some testing it was decided that GSSI structure Scan mini was up for the job.

The first Stage of the contract was for CTS surveyors to attend site specific inductions to allow them to go trackside to carry out the surveys.

The Stage 1 Site Surveys were carried out by a Utility Surveyor using the structure Scan mini and the second surveyor collecting data which had been marked on the platform, we learnt quickly and found that there were Steel rebar back form the platform edge that gave a very good indication as to what was going on inside the concrete, although this was not part of the spec CTS management insisted on collecting this data to help build a picture of what was in concrete, this proved valuable information at a later stage and helped with understanding the GPR graphs that were be analysed on site.

The surveyor’s confidence was building from this and he soon got the knack for identifying the GFRP rebar that wasn’t showing to well at first. The surveyors worked as a team and with their setting out producers working well they covered over a 1000 meters with the structure Scan mini marking all the steel rebar and GFRP rebar that they could see on the screen of the structure Scan mini. Spaced at approximately 200mm apart they recorded 3500 pieces of steel & GFRP Rebar. But it didn’t stop there.

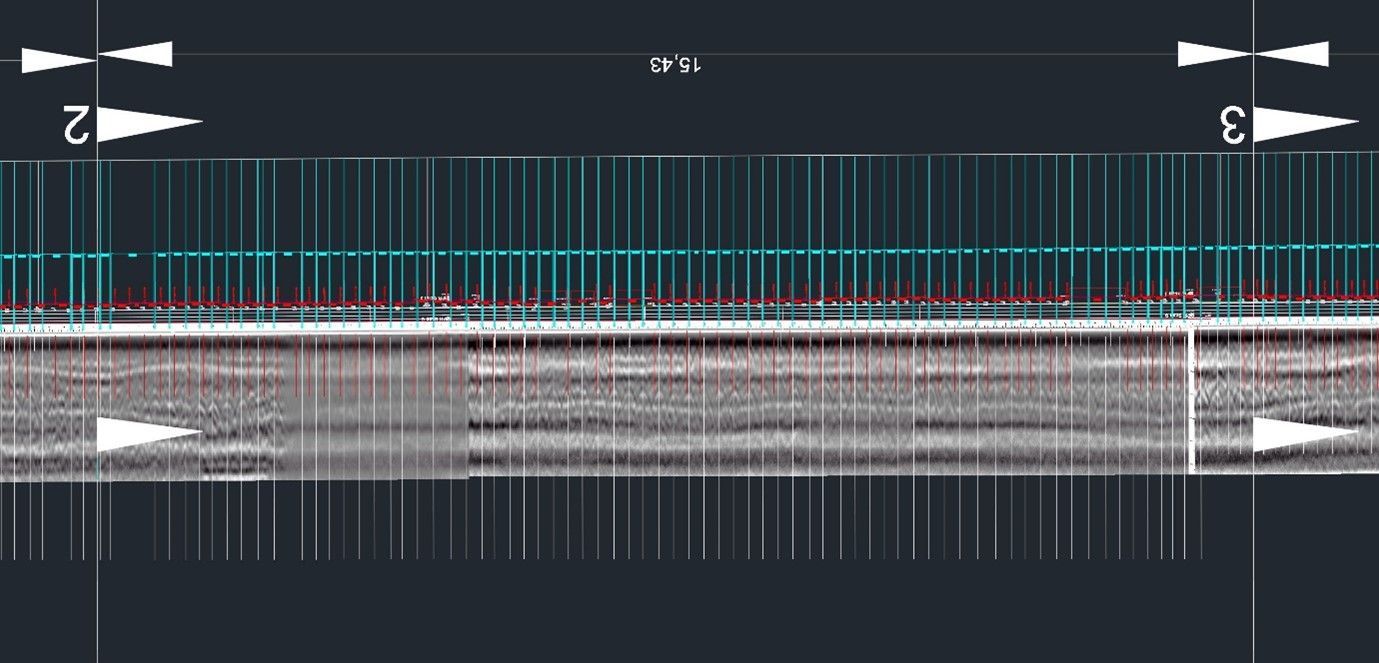

Stage 2 was carried out at the CTS design office were we started looking at the raw Data.

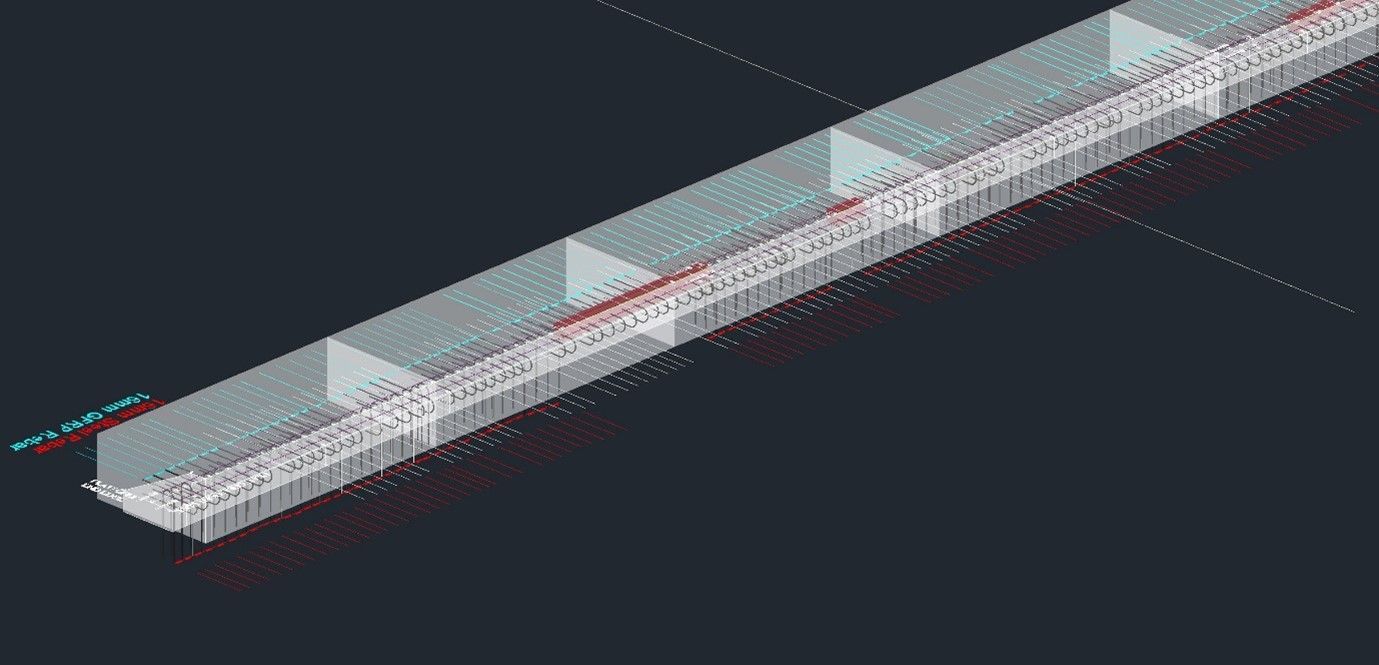

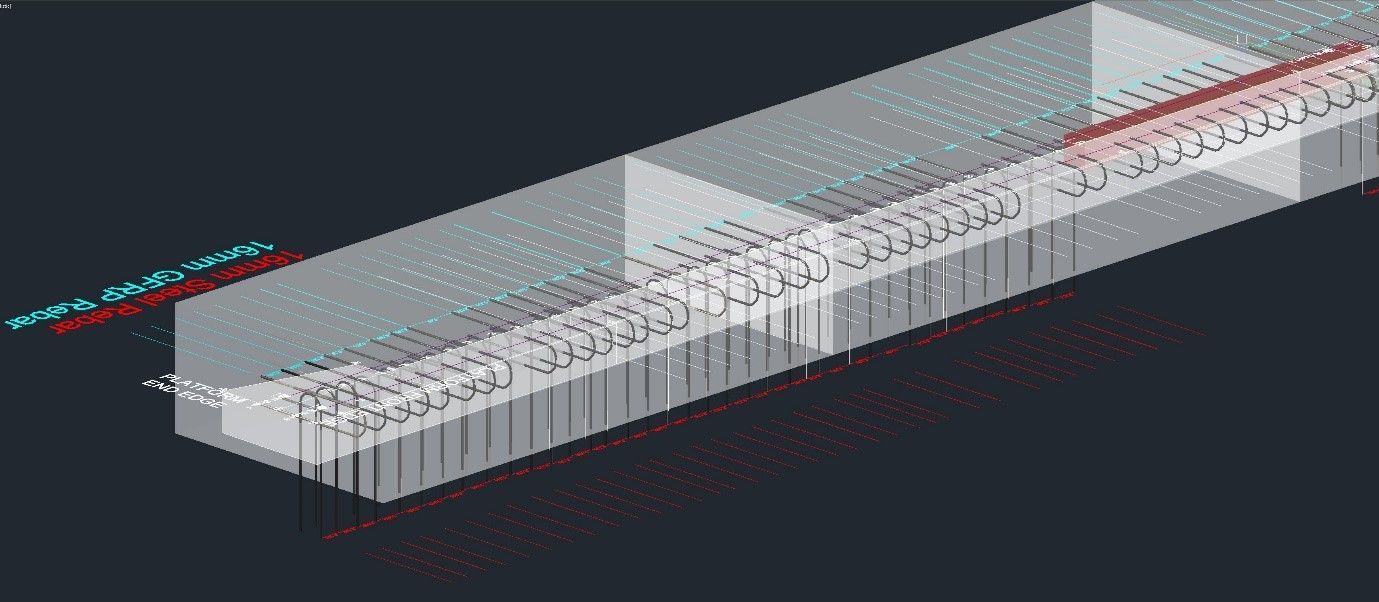

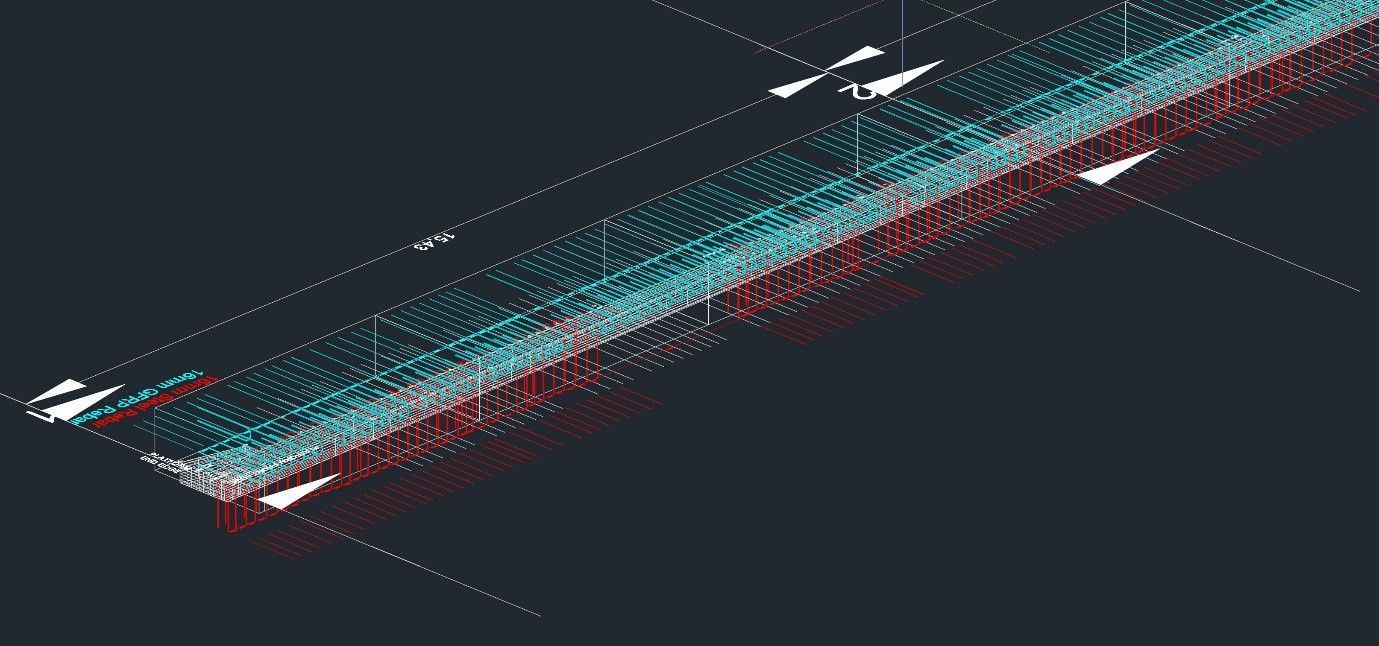

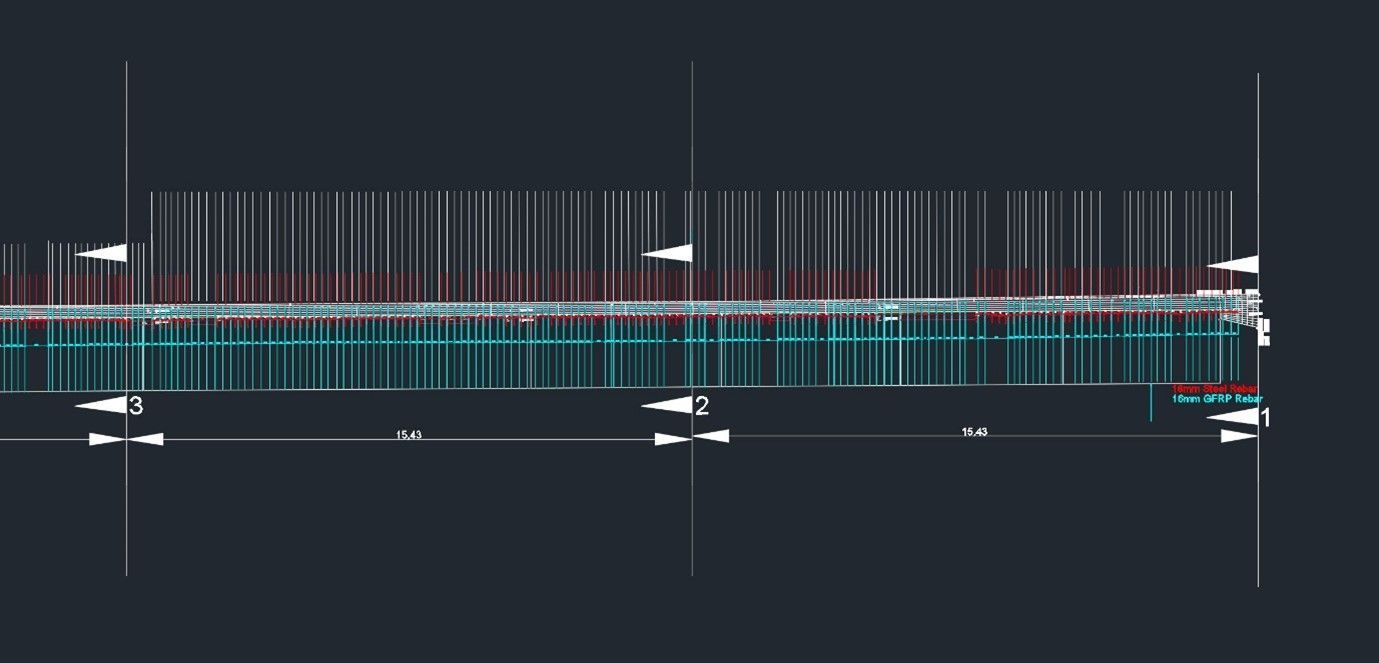

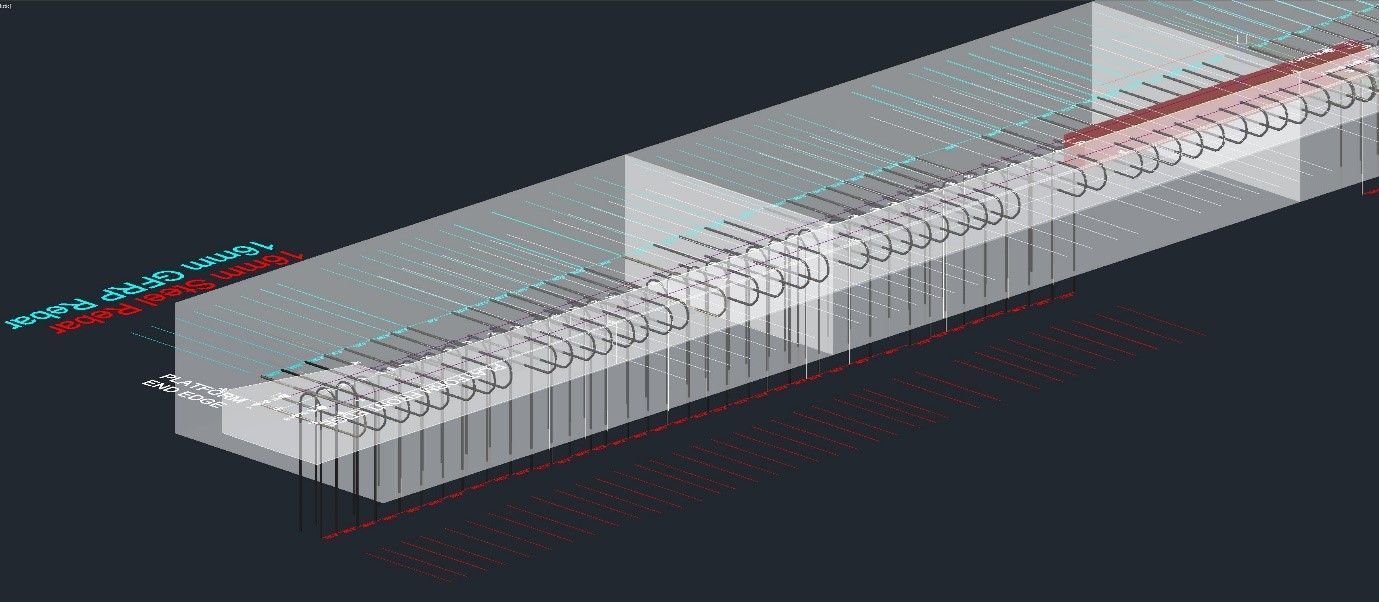

It was decided to build a decent picture of what was going on in concrete and to help visualise this a 3D model started to take shape,

The Cad Ops first built the platform and then placed the rebar at every point that was collected to identify either the steel or GFRP rebar. They were placed at a given average from the front face and the top the platform.

Once this process was complete we were a bit stuck, all of a sudden we had a huge amount of GFRP rebar missing, it was then we conceived a process to accurately place the missing rebar in the model. Using our Cad Skills, we scaled in the GPR graphs and then analysed all the data, it was becoming clearer and using a 4K PC we were able to place in the missing rebar from the graphs that we couldn’t see on the structure scans mini screen.

That was it, we found this processor worked well and we could validate our survey drawing with the GPR graphs, this was showed to the client who agreed the data output had been verified and was convincing enough to proceed to their next stage.

The data was presented in project folders with the 3D cad model DWG exported to a 3D PDF as well as top view 2d wireframe pdfs. The GPR Scans were imbedded within the Cad model for viewing purposes.

This was overall a challenging process of which we all learnt new skills and are now very confident in this process, ironically the last day on site we had been given the opportunity of testing the New GGSI XT machine which had just arrived into the country, we found this machine enhanced the readings and showed a clearer picture of the concrete and rebar.

© Copyright CTS Ltd. 2023